| |

| |

|

|

|

|

|

| |

Product Range |

|

| |

|

|

| |

PRIME Pipes are made of best quality virgin HDPE material in order to prevent degradation of material during the piping processing and to provide outstanding performance during the usage of pipe.

PRIME ISI HDPE Pipes are available from 20 – 315mm as Per IS: 4984 - 95. Both moulded as well as fabricated fittings are available up to 315mm. |

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

| |

Quality Standars And Certification |

|

| |

|

|

| |

PRIME HDPE Pipes are produced as per IS: 4984 - 95 standards in various Sizes / Pressure and available in straight lengths and coils in PE-63,80 & 100 materials

PRIME Products are produced under strict quality control adopted at every stage of production /Working Instructions i.e. Mixing of additives, heating at appropriate temperature, Extrusion Process, Cooling Process, cutting to the various sizes and stacking at proper place for storage. Products are tested for a thorough and vigorous QUALITY Checks as per ISO standards. Our Production /Supply capacity – al put to gather is up to 250-300 MTM.

Test Certificates obtained from CIPET & RELIANCE INDUSTRIES LTD. proves that PRIME Pipes are hygienic and have no adverse effect on the quality (taste + odour) properties of drinking water and can be used for both open and exposed applications. |

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

| |

Features / Advantages |

|

| |

|

|

| |

- CORROSION RESISTANT – for longer life

- HIGH IMPACT STRENGTH

- EXTREAMELY LIGHT WEIGHT – easy to handle

- FLEXIBLE AND HIGH ABRASION RESISTANT – no breakage

- EXCELLENT FLOW CHARASTERISTIC – significant energy saving

- FOOD GRADE - maintain quality of fluid / drinking water

- EASY AND ECONOMICAL INSTALLATION

- HIGH UV RESISTANT - resistant to environmental buildup

- RESISTANT TO SCALING

- EASY MAINTENANCE

|

|

| |

|

|

| |

|

|

|

|

|

| |

Applications |

|

| |

|

|

| |

WATER SUPPLY SYSTEM

- POTABLE WATER SYPPLY DISTRIBUTION

- BOREWELL APPLICATION

- LIFT IRRIGATION / SYPHON IRRIGATION

- SUCTION AND DELIVERY LINES FOR JET / CENTRIFUGAL PUMPS

INDUSTRIAL APPLICATIONS

- DISPOSAL OF CORROSIVE EFFLUENT WASTE

- TRANSPORTATION OF LIQUID FOOD PRODUCTS AND CHEMICALS

- COOLING WATER AND SLURRY DISPOSAL

- SAND STOWING AND SLURRY TRANSPORTATION IN MINES

- DUCTS FOR HVAC SYSTEMS

ENVIRONMENTAL PROTECTION

- EFFLUENT TREATMENT / WATER TREATMENT PLANTS

- DRAINAGE AND SEWERAGE

- DISPOSAL OF SAND & SLURRY IN DREGING OPERATION

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

| |

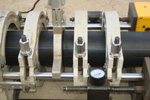

Joining Procedure |

|

| |

|

|

| |

|

| Step 1: Set the welding Machine and put it on heat. |

|

|

| Step 2: Set the pipe and align both the pipes before heating the pipe |

|

|

| Step 3: Once machine is heated and pipes are aligned, place the welding plate on to the machine |

|

|

| Step 4: push the pipe towards the heating plate and allow it to heat. |

|

|

| Step 5: Remove the heating plate and push the pipe towards each other so that heated portion will fuse with each other making it a perfect leak proof joint. |

|

|

| Step 6: once pipe is cooled, it can be removed and used for the desired application. |

|

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

| |

Our Reputed Clients |

|

| |

|

|

| |

The Group has established an amicable relationship with our high profile clients spread over the south states through our supply of quality products for sanitation application at reasonably competitive price as is directly proportionate to the satisfaction of our valuable customers |

|

| |

|

|

| |

Listed below are few of our reputed clients. |

|

| |

| Wipro Ltd. |

| Infosys Ltd. |

| GE (India) |

| HLL |

| PG Pipeline Engineering |

| TATA BP Solar |

| Maxel Engineers |

| Madras Engineering |

| Kamdhar Exports |

| Gemini Exports |

| Purvankara Projects |

|

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

| |

Technical Comparisons & Data Sheet |

|

| |

|

|

| |

Comparison between PRIME ISI HDPE & Other pipes |

|

| |

|

|

| |

| Particulars |

PRIME HDPE |

PVC |

GI |

| Life |

> 50 years |

< 10 years |

< 10 years |

| Maintenance |

Virtually maintenance free |

Being brittle in nature, requires frequent maintenance |

Being corrosive in nature requires frequent maintenance |

| Weight |

Light weight, easy to handle and transport |

Light in weight but brittle in nature may cause transportation problems. |

Heavy. Difficult to handle / transport |

| Installation |

Very easy |

Easy |

Difficult and time consuming. |

| Flexibility |

Being flexible, can be coiled up to 110mm, helps in fast installation with less joints |

Almost rigid, can be supplied only in maximum lengths of 6 meter. |

Rigid. Supplied in lengths of 6 meters. |

| Corrosion |

NO corrosion |

No corrosion |

Highly corrosive |

| Food Grade |

HDPE is food grade |

Not recommended |

Not recommended |

| Weathering |

Highly resistant even in extreme weather conditions |

Very Poor. Tends to break when exposed to sun |

Very Poor. Tends to corrode. |

| Temperature resistance |

Very Good |

Poor |

Poor |

| Chemical Resistance |

Good Resistance to Acids & Alkalies |

Comparatively Poor |

Poor |

| Soil Settlement |

Adjust itself to soil settlement and can resist heavy load |

Tends to crack in uneven soil conditions. |

Can not adjust it to soil conditions. |

| Impact Strength |

Excelent |

Poor |

Moderate |

| Joints |

Leak proof joints |

Poor adhesive joints may leak – needs replacement |

Once corroded – tends to leak. Require frequent maintenance. |

|

|

|

| |

|

|

| |

PRIME HDPE PIPE : WALL THICKNESS CHART IS:4984-95 PE63 (Fig. in mm) |

|

| |

| OD Nominal |

OD Tolerance |

Ovality Tolerance |

PN |

2.5 |

PN |

4 |

PN |

6 |

PN |

8 |

PN |

10 |

PN |

12.5 |

PN |

16 |

| Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

| 20 |

0.3 |

1.2 |

|

|

|

|

|

|

|

|

2.3 |

2.8 |

2.8 |

3.3 |

3.4 |

4.0 |

| 25 |

0.3 |

1.2 |

|

|

|

|

|

|

2.3 |

2.8 |

2.8 |

3.3 |

3.4 |

4.0 |

4.2 |

4.9 |

| 32 |

0.3 |

1.3 |

|

|

|

|

2.3 |

2.8 |

3.0 |

3.5 |

3.6 |

4.2 |

4.4 |

5.1 |

5.4 |

6.2 |

| 40 |

0.4 |

1.4 |

|

|

2.0 |

2.4 |

2.8 |

3.3 |

3.7 |

4.3 |

4.5 |

5.2 |

5.5 |

6.3 |

6.7 |

7.6 |

| 50 |

0.5 |

1.4 |

|

|

2.4 |

2.9 |

3.5 |

4.1 |

4.6 |

5.3 |

5.6 |

6.4 |

6.8 |

7.7 |

8.4 |

9.5 |

| 63 |

0.6 |

1.5 |

2.0 |

2.4 |

3.0 |

3.5 |

4.4 |

5.1 |

5.8 |

6.6 |

7.0 |

7.9 |

8.6 |

9.7 |

10.5 |

11.8 |

| 75 |

0.7 |

1.6 |

2.3 |

2.8 |

3.6 |

4.2 |

5.3 |

6.1 |

6.9 |

7.8 |

8.4 |

9.5 |

10.2 |

11.5 |

12.5 |

14.0 |

| 90 |

0.9 |

1.8 |

2.8 |

3.3 |

4.3 |

5.0 |

6.3 |

7.2 |

8.2 |

9.3 |

10.0 |

11.2 |

12.2 |

13.7 |

15.0 |

16.7 |

| 110 |

1.0 |

2.2 |

3.4 |

4.0 |

5.3 |

6.1 |

7.7 |

8.7 |

10.0 |

11.2 |

12.3 |

13.8 |

14.9 |

16.6 |

28.4 |

20.5 |

| 125 |

1.2 |

2.5 |

3.8 |

4.4 |

6.0 |

6.8 |

8.8 |

9.9 |

11.4 |

12.8 |

13.9 |

15.5 |

16.9 |

18.8 |

20.9 |

23.2 |

| 140 |

1.3 |

2.8 |

4.3 |

5.0 |

6.7 |

7.6 |

9.8 |

11.0 |

12.8 |

14.3 |

15.6 |

17.4 |

19.0 |

21.1 |

23.4 |

26.0 |

| 160 |

1.5 |

3.2 |

4.9 |

5.6 |

7.7 |

8.7 |

11.2 |

12.6 |

14.6 |

16.3 |

17.8 |

19.8 |

21.7 |

24.1 |

26.7 |

29.6 |

| 180 |

1.7 |

3.6 |

5.5 |

6.3 |

8.6 |

9.7 |

12.6 |

14.1 |

16.4 |

18.3 |

20.0 |

22.2 |

24.4 |

27.1 |

30.0 |

33.2 |

| 200 |

1.8 |

4.0 |

6.1 |

7.0 |

9.6 |

10.8 |

14.0 |

15.6 |

18.2 |

20.3 |

22.3 |

24.8 |

27.1 |

30.1 |

33.4 |

37.0 |

| 225 |

2.1 |

4.5 |

6.9 |

7.8 |

10.8 |

12.1 |

15.7 |

17.5 |

10.5 |

22.8 |

25.0 |

27.7 |

30.5 |

33.8 |

37.5 |

41.5 |

| 250 |

2.3 |

5.0 |

7.6 |

8.6 |

12.0 |

13.4 |

17.5 |

19.5 |

22.8 |

25.3 |

27.8 |

30.8 |

33.8 |

37.4 |

41.7 |

46.1 |

| 280 |

2.6 |

9.8 |

8.5 |

9.6 |

13.4 |

15.0 |

19.6 |

21.8 |

25.5 |

28.3 |

31.2 |

34.6 |

37.9 |

41.9 |

46.7 |

51.6 |

| 315 |

2.9 |

11.1 |

9.6 |

10.8 |

15.0 |

16.7 |

22.0 |

24.4 |

28.7 |

31.8 |

35.0 |

38.7 |

42.6 |

47.1 |

52.5 |

58.0 |

|

|

|

| |

|

|

| |

PRIME HDPE PIPE : WALL THICKNESS CHART IS:4984-95 PE80 (Fig. in mm) |

|

| |

| OD Nominal |

OD Tolerance |

Ovality Tolerance |

PN |

2.5 |

PN |

4 |

PN |

6 |

PN |

8 |

PN |

10 |

PN |

12.5 |

PN |

16 |

| Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

| 20 |

0.3 |

1.2 |

|

|

|

|

|

|

|

|

|

|

2.3 |

2.8 |

2.8 |

3.3 |

| 25 |

0.3 |

1.2 |

|

|

|

|

|

|

|

|

2.3 |

2.8 |

2.8 |

3.3 |

3.5 |

4.1 |

| 32 |

0.3 |

1.3 |

|

|

|

|

|

|

2.4 |

2.9 |

3.0 |

3.5 |

3.6 |

4.2 |

4.5 |

5.2 |

| 40 |

0.4 |

1.4 |

|

|

|

|

2.3 |

2.8 |

3.0 |

3.5 |

3.7 |

4.3 |

4.5 |

5.2 |

5.6 |

6.4 |

| 50 |

0.5 |

1.4 |

|

|

2.3 |

2.8 |

2.9 |

3.4 |

3.8 |

4.4 |

4.6 |

5.3 |

5.6 |

6.4 |

6.9 |

7.8 |

| 63 |

0.6 |

1.5 |

|

|

2.5 |

3.0 |

3.6 |

4.2 |

4.7 |

5.4 |

5.8 |

6.6 |

7.0 |

7.9 |

8.7 |

9.8 |

| 75 |

0.7 |

1.6 |

|

|

2.9 |

3.4 |

4.3 |

5.0 |

5.6 |

6.4 |

6.9 |

7.8 |

8.4 |

9.5 |

10.4 |

11.7 |

| 90 |

0.9 |

1.8 |

2.3 |

2.8 |

3.5 |

4.1 |

5.1 |

5.9 |

6.7 |

7.6 |

8.2 |

9.3 |

10.0 |

11.2 |

12.5 |

14.0 |

| 110 |

1.0 |

2.2 |

2.7 |

3.2 |

4.3 |

5.0 |

6.3 |

7.2 |

8.2 |

9.3 |

10.0 |

11.2 |

12.3 |

13.8 |

15.2 |

17.0 |

| 125 |

1.2 |

2.5 |

3.1 |

3.7 |

4.9 |

5.6 |

7.1 |

8.1 |

9.3 |

10.5 |

11.4 |

12.8 |

13.9 |

15.5 |

17.3 |

19.3 |

| 140 |

1.3 |

2.8 |

3.5 |

4.1 |

5.4 |

6.2 |

8.0 |

9.0 |

10.4 |

11.7 |

12.8 |

14.3 |

15.6 |

17.4 |

19.4 |

21.6 |

| 160 |

1.5 |

3.2 |

4.0 |

4.6 |

6.2 |

7.1 |

9.1 |

10.3 |

11.9 |

13.3 |

14.6 |

16.3 |

17.8 |

19.8 |

22.1 |

24.6 |

| 180 |

1.7 |

3.6 |

4.4 |

5.1 |

7.0 |

7.9 |

10.2 |

11.5 |

13.4 |

15.0 |

16.4 |

18.3 |

20.0 |

22.2 |

24.9 |

27.6 |

| 200 |

1.8 |

4.0 |

4.9 |

5.6 |

7.7 |

8.7 |

11.4 |

12.8 |

14.9 |

16.6 |

18.2 |

20.3 |

22.3 |

24.8 |

27.6 |

30.6 |

| 225 |

2.1 |

4.5 |

5.5 |

6.3 |

8.7 |

9.8 |

12.8 |

14.3 |

16.7 |

18.6 |

20.5 |

22.8 |

25.0 |

27.7 |

31.1 |

34.5 |

| 250 |

2.3 |

5.0 |

6.1 |

7.0 |

9.7 |

10.9 |

14.2 |

15.9 |

18.6 |

20.7 |

22.8 |

25.3 |

27.8 |

30.8 |

34.5 |

38.2 |

| 280 |

2.6 |

9.8 |

6.9 |

7.8 |

10.8 |

12.1 |

15.9 |

17.7 |

20.8 |

23.1 |

25.5 |

28.3 |

31.2 |

34.6 |

38.7 |

42.8 |

| 315 |

2.9 |

11.1 |

7.7 |

8.7 |

12.2 |

13.7 |

17.9 |

19.9 |

23.4 |

26.0 |

28.7 |

31.8 |

35.0 |

38.7 |

43.5 |

48.1 |

|

|

|

| |

|

|

| |

PRIME HDPE PIPE : WALL THICKNESS CHART IS:4984-95 PE100 (Fig. in mm) |

|

| |

| OD Nominal |

OD Tolerance |

Ovality Tolerance |

PN |

6 |

PN |

8 |

PN |

10 |

PN |

12.5 |

PN |

16 |

| Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

Min |

Max |

| 20 |

0.3 |

1.2 |

|

|

|

|

|

|

|

|

2.3 |

2.8 |

| 25 |

0.3 |

1.2 |

|

|

|

|

|

|

2.3 |

2.8 |

2.9 |

3.4 |

| 32 |

0.3 |

1.3 |

|

|

|

|

2.4 |

2.9 |

2.9 |

3.4 |

3.7 |

4.3 |

| 40 |

0.4 |

1.4 |

|

|

2.4 |

2.9 |

3.0 |

3.5 |

3.7 |

4.3 |

4.6 |

5.3 |

| 50 |

0.5 |

1.4 |

2.3 |

2.8 |

3.0 |

3.5 |

3.7 |

4.3 |

4.6 |

5.3 |

5.7 |

6.5 |

| 63 |

0.6 |

1.5 |

2.9 |

3.4 |

3.8 |

4.4 |

4.7 |

5.4 |

5.7 |

6.5 |

7.1 |

8.1 |

| 75 |

0.7 |

1.6 |

3.5 |

4.1 |

4.5 |

5.2 |

5.6 |

6.4 |

6.8 |

7.7 |

8.5 |

9.6 |

| 90 |

0.9 |

1.8 |

4.1 |

4.8 |

5.4 |

6.2 |

6.7 |

7.6 |

8.2 |

9.3 |

10.2 |

11.5 |

| 110 |

1.0 |

2.2 |

5.0 |

5.7 |

6.6 |

7.5 |

8.1 |

9.2 |

10.0 |

11.2 |

12.4 |

13.9 |

| 125 |

1.2 |

2.5 |

5.7 |

6.5 |

7.5 |

8.5 |

9.2 |

10.4 |

11.3 |

12.7 |

14.1 |

15.8 |

| 140 |

1.3 |

2.8 |

6.4 |

7.3 |

8.4 |

9.5 |

10.3 |

11.6 |

12.7 |

14.2 |

15.8 |

17.6 |

| 160 |

1.5 |

3.2 |

7.3 |

8.3 |

9.6 |

10.8 |

11.8 |

13.2 |

14.5 |

16.2 |

18.1 |

20.2 |

| 180 |

1.7 |

3.6 |

8.3 |

9.3 |

10.8 |

12.1 |

13.3 |

14.9 |

16.3 |

18.2 |

20.3 |

22.6 |

| 200 |

1.8 |

4.0 |

9.3 |

10.3 |

12.0 |

13.4 |

14.8 |

16.5 |

18.1 |

20.2 |

22.6 |

25.1 |

| 225 |

2.1 |

4.5 |

10.3 |

11.6 |

13.5 |

15.1 |

16.6 |

18.5 |

20.4 |

22.7 |

25.4 |

28.2 |

| 250 |

2.3 |

5.0 |

11.4 |

12.8 |

15.0 |

16.7 |

18.4 |

20.5 |

22.6 |

25.1 |

28.2 |

31.3 |

| 280 |

2.6 |

9.8 |

12.8 |

14.3 |

16.8 |

18.7 |

20.6 |

22.9 |

25.3 |

28.1 |

31.6 |

35.0 |

| 315 |

2.9 |

11.1 |

14.4 |

16.1 |

18.9 |

21.0 |

23.2 |

25.8 |

28.5 |

31.6 |

35.5 |

39.3 |

|

|

|

| |

|

|

| |

|

|

| |

|

|